Clay Brick Production Line

The main raw material of clay bricks are silty clay or sandy clay, and the main chemical composition are SiO2, Al2O3 and Fe2O3 and crystalline water. Due to the different geological conditions, clay may also contains small amounts of metal oxides of alkali and alkaline earth.

The content of impurities in raw materials clay can bring great impact on the clay bricks calcination temperature and brick color. Clay is the main raw material of clay brick production, but it also can mix with other raw materials such as shale, coal gangue, fly ash, etc. to produce sintered bricks since their chemical composition is similar to clay. But these materials have bad plasticity, so it often need to add a certain amount of clay to meet the plasticity needs of adobe shaping. In addition, coal gangue and fly ash in the adobe brick are combustible industrial waste, containing unburned carbon, which burn inside adobe during sintering, thus saving a lot of firing coal investment. Such bricks also known as internal combustion brick or semi internal combustion brick.

The images below show the Nepal clay and Bangladesh clay brick sample.

See more raw material for brick making

Clay brick manufacturing process: clay treatment, brick making, brick setting, drying/roasting, finish brick packing. Capacity: 300-800t/day

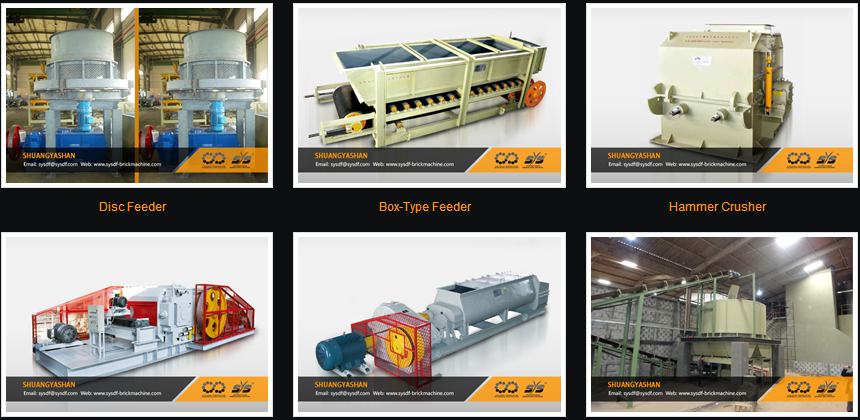

Clay Treatment Machine

For clay treatment, Shuangyashan provides advanced machines such as crusher, mixer, pan mill, bucket excavator, belt conveyor, box type feeder, etc.

Brick Making Machine

The main equipment for clay production line is brick making machine, wich is a vacuum brick extruder for brick strips shaping and extruding.

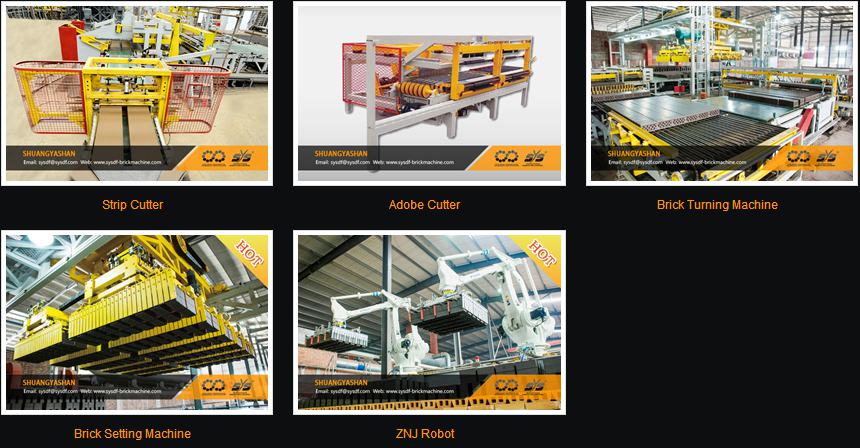

Brick Setting Machine

Brick setting machines are very important for automatic clay brick production line, including brick cutting machine, brick turning machine, robot brick setting machine, etc.

Drying and Roasting

Shuangyashan offer kiln system constraction and solutions and we can carry out drying chamber and kiln building for customers.

Finish Brick Packing

The sintered clay bricks are treated by brick unloading system and brick packing system. Trust that we can help you carry out fully automatic clay brick production line.