product list

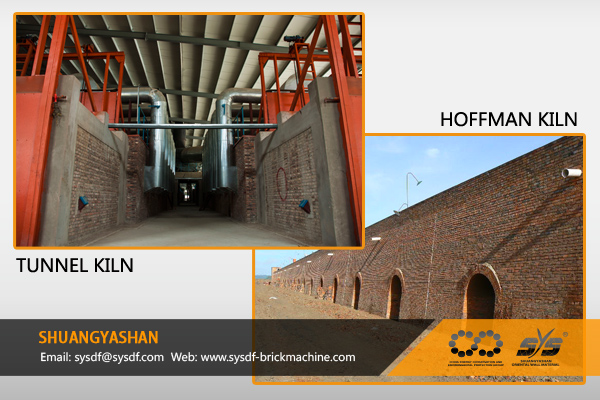

Comparison of Tunnel Kiln and Hoffman Kiln

1. The brick setting and stacking are carried out outside the tunnel kiln, finished bricks unloading is also carried out outside the kiln, which makes good working condition for workers. The installation, kiln car can be easier for mechanization. While for Hoffman kiln, the brick setting, stacking and unloading are carried out inside the kiln. The working conditions are with high ambient temperatures, big dust, poor operating conditions and equipment, the kiln is difficult to mechanization.

2. Tunnel kiln is designated firing kiln, and the temperature of kiln walls and roof of is constant with stable heat source. While Hoffman kiln is designed with cycle firing and heating, cooling the kiln walls and with labile heating. That is to say the thermal efficiency of tunnel kiln is higher than that of Hoffman kiln. However, the tunnel kiln need cycle heating and cooling kiln cars, increasing heat loss.

3. In the normal production, once the tunnel kiln gate is established, it no longer need to move. While the Hoffman kiln need to start gate and drop gate according to fire conditions.

4. There is less brake valve in tunnel kiln, which is mainly arranged in preheating zone of fire forward direction, and the majority valve is enabled. The valves have to be arranged around the Hoffman kiln in larger quantities, and most of them are in inactive state. It is difficult to keep these unused gate tightly sealed. At negative pressure please, cool air outside the kiln will induct to kiln, while at the positive pressure please, the hot air is pressurized outside the kiln, produce a large amount of leakage. Because most of these gates are not at he fire forward direction preheating zone, so the restrain fire speed.

For example: A plant has a 97.84m * 3.06m tunnel kiln, 9 pairs (18) gates, among which seven pairs of them are smoke gates, located in the preheating zone; one pair is vehicle gates, also at preheating zone; one pair high-temperature heat discharge gates, at the beginning of the firing zone, near to preheating zone. Both the using brake and not using gate "together" pull fire to forward direction, no reverse force generation. B plant has a 24-door Hoffman kiln, and there are 50 air gates inside and outside the kiln. There are 3/5 vales in the reverse position. Once these gate leakage happens, it inevitably produces adverse force, hinder the forward of fire.

5. Tunnel kiln is designed with less coal feeding hole, and most of them are arranged around the central point of zero pressure, it does not leak out or leak in any gas. There are large mount of coal hole around the Hoffman kiln with various pressure conditions, so there are much gas leakage.

For example: A plant has a 127 coal feeding hole tunnel kiln, and B plant has a 526 coal hole Hoffman kiln, 4 times more than the tunnel kiln.

6. By using automatic coal casting machine, or gas, liquid fuel for firing, it is much easier for installation of these systems on the tunnel kiln, much simpler than that set in the Hoffman kiln.

7. Hoffman kiln need to paste paper mask, and air leak happens. The tunnel kiln is paperless blocked.

8. Under normal circumstances, Hoffman kiln has much more leak point than tunnel kiln, so its fire speed is slow than tunnel kiln. Fire speed of tunnel kiln is 3.5 ~ 4m / h while the fire speed of Hoffman Kiln is 2.5 ~ 3m / h or below, so the smaller cross-sectional area of tunnel kiln often yield higher than the larger cross-sectional area Hoffman kiln.

9. Hoffman kiln need to be set up more number of doors around with larger workload of frequent closing doors, opening hole , and the door is the weak link with less heat, so the bricks close to the kiln door are generally less fired. The tunnel kiln has only 2 doors. But we need to point out that the entrance of tunnel kiln car is near to the exhaust fan with large negative pressure, if the seal is not good, a lot of outside cold air leak into the kiln (the leaking cold air may up to 10,000 Nm³ / h or more) and into exhaust fan nearby. So the time of kiln door open shall be as short as possible, preferably set double kiln door at the entrance.